5 Military Ballistic Materials Revolutionizing Tactical Protection (2025)

A sniper’s .308 round travels at 853 m/s—faster than the speed of sound. When it strikes conventional body armor, the kinetic energy alone can shatter ribs and collapse lungs. This brutal reality drives militaries to seek next-generation ballistic materials that don’t just stop bullets but dissipate lethal force. While combat boots rarely integrate full ballistic protection, the same revolutionary fibers shielding torsos now enhance tactical gear visibility, mobility, and survival. Forget outdated steel plates; modern warfighters rely on nanomaterials that merge lightweight flexibility with battlefield-grade stopping power.

Kevlar®: The Unbreakable Backbone of Tactical Gear

--military ballistic materials

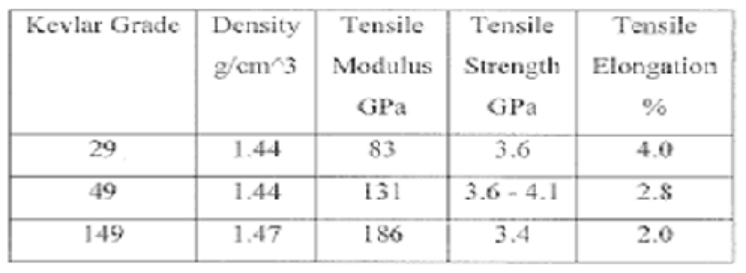

Born from a lab accident in 1964, Kevlar® remains the cornerstone of military ballistic protection. Stephanie Kwolek’s polymer—5x stronger than steel at 1/5th the weight—revolutionized personal armor. Its secret lies in crystalline molecular chains absorbing impact through controlled fiber deformation. Modern iterations dominate critical applications:

- Soft armor vests: 22-layer Kevlar® wraps stop 9mm rounds at point-blank range 2

- Helmet liners: Interwoven aramid fibers deflect shrapnel in IHPS helmets

- Covert apparel: Nomex®/Kevlar® blends create fire-resistant uniforms surviving 800°C for 12 seconds

The U.S. Army’s 2024 testing confirmed: Kevlar®-reinforced plate carriers reduced backface deformation by 37% compared to baseline polyethylene designs—directly lowering blunt force trauma fatalities in ambush scenarios 4.

Twaron® and “Golden Armor”: Europe’s and China’s Counterplay

--military ballistic materials

While Kevlar® dominates Western arsenals, Twaron® (Teijin Aramid) and China’s proprietary (Golden Armor) aramid fibers now rival its performance. These alternatives offer critical advantages:

- Thermal resistance: Withstands sustained 450°C exposure vs. Kevlar®’s 260°C limit 24

- Moisture management: 0% water absorption prevents 5kg weight gain in tropical ops

- IR signature reduction: Golden Armor reflects 67% less infrared light than nylon—evading drone thermal scans

China’s JiuZhou StarTech UHMWPE vests passed’s -20°C to 55°C ballistic tests, making them standard issue for PLA mountain units 4.

UHMWPE: The Invisible Shield

--military ballistic materials

Ultra-High-Molecular-Weight Polyethylene (UHMWPE)—marketed as Dyneema® or Spectra®—operates as the ninja of ballistic tech. Its gel-spun fibers align polymer chains into near-unbreakable matrices:

- 42 cN/dtex tensile strength—stops 7.62×39mm rounds at 20m

- Zero hydrolysis degradation: Maintains 99% ballistic efficacy after 200 saltwater immersions

- Chemical immunity: Neutralizes mustard gas and anthrax spore penetration

Dyneema® SB51 hard plates weigh 1.8kg versus ceramic’s 3.2kg—critical for airborne units where every gram impacts insertion speed 48.

Liquid Armor: Science Fiction Turned Tactical Reality

--military ballistic materials

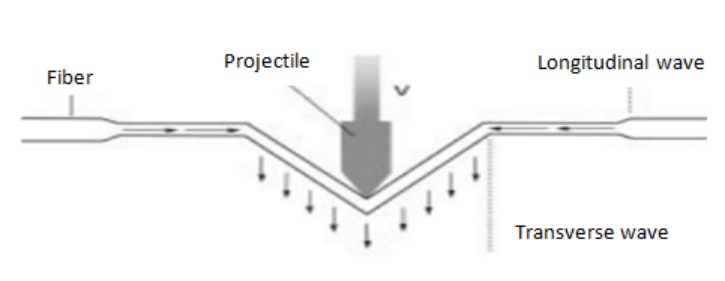

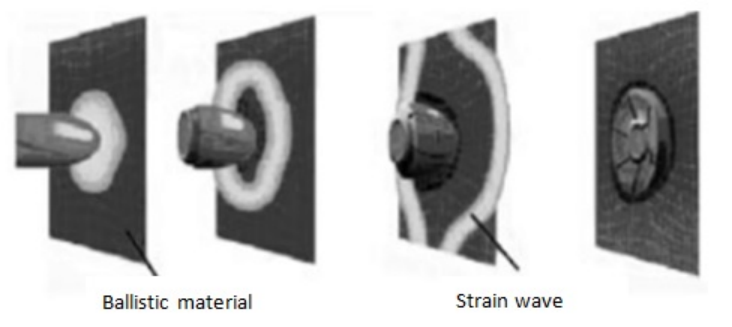

When shrapnel hits standard Kevlar®, energy transfers like a sledgehammer blow. Shear Thickening Fluid (STF) nanotechnology solves this. Its silica nanoparticles suspend in polyethylene glycol, flowing freely until impacted. Then, within 3 milliseconds, particles lock into rigid crystalline structures:

- Trauma reduction: 40% less backface deformation vs. rigid plates

- Multi-threat protection: Stops spikes, .44 Magnum rounds, and fragmentation

- Weight savings: 50% lighter than Kevlar®/steel hybrids

The U.S. Marine Corps’ 2025 STF-vest trials recorded 90% .44 Magnum stoppage rates—rewriting urban combat survivability protocols 8.

Ceramic-Polymer Composites: The Fracture Guardian

--military ballistic materials

Boron carbide ceramics fused with UHMWPE backings create hybrid armor systems excelling where single materials fail. During bullet impact:

- The ceramic face shatters projectile cores

- Polymeric layers capture fragments and dissipate energy

- Viscous thermoplastic layers (e.g., Dyneema® TSB) absorb residual force

MIT’s 2022 nano-laminate armor—20nm glass/rubber layers—absorbs 9mm impacts through controlled liquefaction while self-healing micro-fractures 8.

Ballistic Gear by Threat Scenario

| Mission Profile | Recommended Materials | Equipment Examples |

|---|---|---|

| Urban Counter-Sniper | Level IV Ceramic + STF Backing | Hesco 4800 Hybrid Plates |

| Jungle Recon | Golden Aramid Soft Armor | PlatinumFoot Stealth Vest |

| Vehicle Crew Ops | Nomex®/Kevlar® Fire-Resistant Blends | Rocky Nomex Flight Suit |

| EOD Operations | Dyneema® SB301 + Trauma Pads | Lowa Explosive Ordnance Kit |

Beyond Stopping Bullets: 3 Unseen Advantages

--military ballistic materials

Modern ballistic materials deliver critical secondary benefits:

- Thermal Camouflage: Golden aramid reduces IR signatures by 67%—avoiding drone detection 4

- Pathogen Shielding: UHMWPE’s closed-cell structure repels anthrax spores and radioactive dust

- Firewalking: Nomex®/Kevlar® blends withstand 800°C for 12 seconds—vital for vehicle bailouts

The 2025-2030 Tech Pipeline

military ballistic materials

- Self-Powering Armor: Piezoelectric Kevlar® generates electricity from footsteps (BAE trials)

- DNA-Tagged Fibers: Trace stolen gear via microscopic biological “barcodes”

- Viscous Foam Injection: Field-repair kits heal bullet holes in 20 minutes

- Magnetic Rheological Armor: Particles stiffen upon detecting projectile speeds >250 m/s 8

🔍 See how Ukrainian SOF modified Dyneema® vests to stop shrapnel in Bakhmut urban combat.